Laser Shock Peening Setup-cfm-facilities

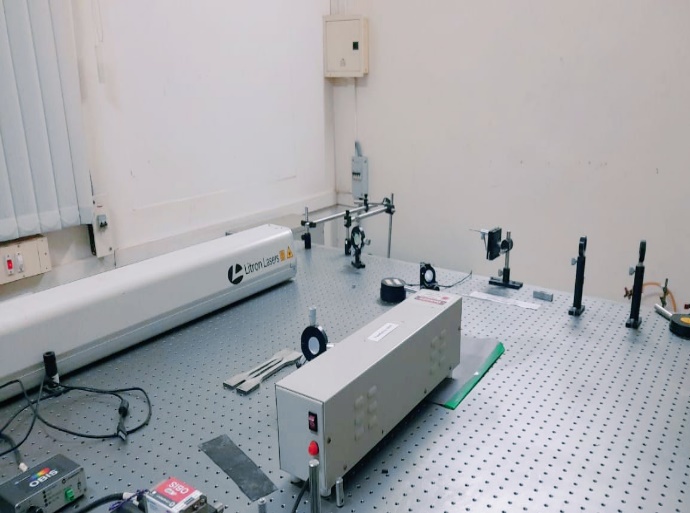

Laser Shock Peening Setup

A process of materials that induces residual compressive stresses on the surface of a component due to shock waves produced by plasma”. Laser peening (LP), or laser shock peening (LSP), is a surface engineering process used to impart beneficial residual stresses in materials. Laser peening uses the dynamic mechanical effects of a shock wave imparted by a laser to modify the surface of a target material. Fundamentally, laser peening can be accomplished with only two components: a transparent overlay and a high energy pulsed laser system. The deep, high-magnitude compressive residual stresses induced by laser peening increase the resistance of materials to surface-related failures, such as fatigue, fretting fatigue and stress corrosion cracking. Laser shock peening can also be used to strengthen thin sections, harden surfaces, shape or straighten parts (known as laser peen forming), break up hard materials, compact powdered metals and for other applications where high pressure, short duration shock waves offer desirable processing results.

Specifications:

- Brand-Litron Lasers

- Laser medium: Nd-YAG Laser

- Energy - 400 mJ

- Laser Wavelength - 1064nm

- Pulsed duration - 6ns

Research Focus:

- Surface Distribution of Residual Stresses

- Thermal stability of Residual Stresses

- In-Depth Residual Stress Distribution