Centre for Biomaterials, Cellular and Molecular Theranostics (CBCMT)

Facilities

HOME Lab (3D Bioprinting Laboratory)

3D bioprinting facilities are a recent addition to our centre. The advanced 3D bioprinting facility is called HOME (Human Organ Manufacturing and Engineering) Lab, equipped with two high-end Cellink BioX bioprinter as well as few basic bioprinters. With this addition, the centre is better positioned to fabricate 3D organoids and tissue mimics, which will be also be one of the key focus areas in coming years.

Lab In-charge: Dr.Arunkumar Palaniappan, Email: arunkumar.p@vit.ac.in

| INSTRUMENTNAME | COMPANY | NUMBER |

|---|---|---|

| 3D BIOPRINTER WITH PNEUMATIC HEAD | CELLINK | 1 |

| 3D BIOPRINTER FOR THERMOPLASTIC POLYMERS | CELLINK | 1 |

| ALFATEK 3D BIOPRINTER | ALFATEK | 2 |

| BSL2 BIOSAFETY CABINET | ESCO BIOTECH | 1 |

| CO2 INCUBATOR | ESCO BIOTECH | 1 |

| INVERTED MICROSCOPE | MAGNUS | 1 |

| COOLING CENTRIFUGE | REMI | 2 |

| ANALYTICAL BALANCE | SARTORIOUS | 1 |

| DIGITAL 5 POSITION MAGNETIC STIRRER | REMI | 1 |

| MAGNETIC STIRRER | TARSON | 1 |

| PH METER | SYSTRONICS | 1 |

| FREEZE DRIER | MARTIN CHRIST | 1 |

| VORTEX MIXER | REMI | 1 |

| MICROBALANCE | SHIMADZU-UNIBOC | 1 |

| SPINWIN MICRO CENTRIFUGE | TARSON | 1 |

| CLINICAL CENTIFUGE | REMI | 1 |

| HOT AIR OVEN | TECHNICO LAB PRODUCT | 1 |

| AUTOCLAVE | BIOTECH ENGINEERING | 1 |

| REFRIGERATOR | LG | 1 |

Confocal Microscopy Facility

Drug Discovery Unit

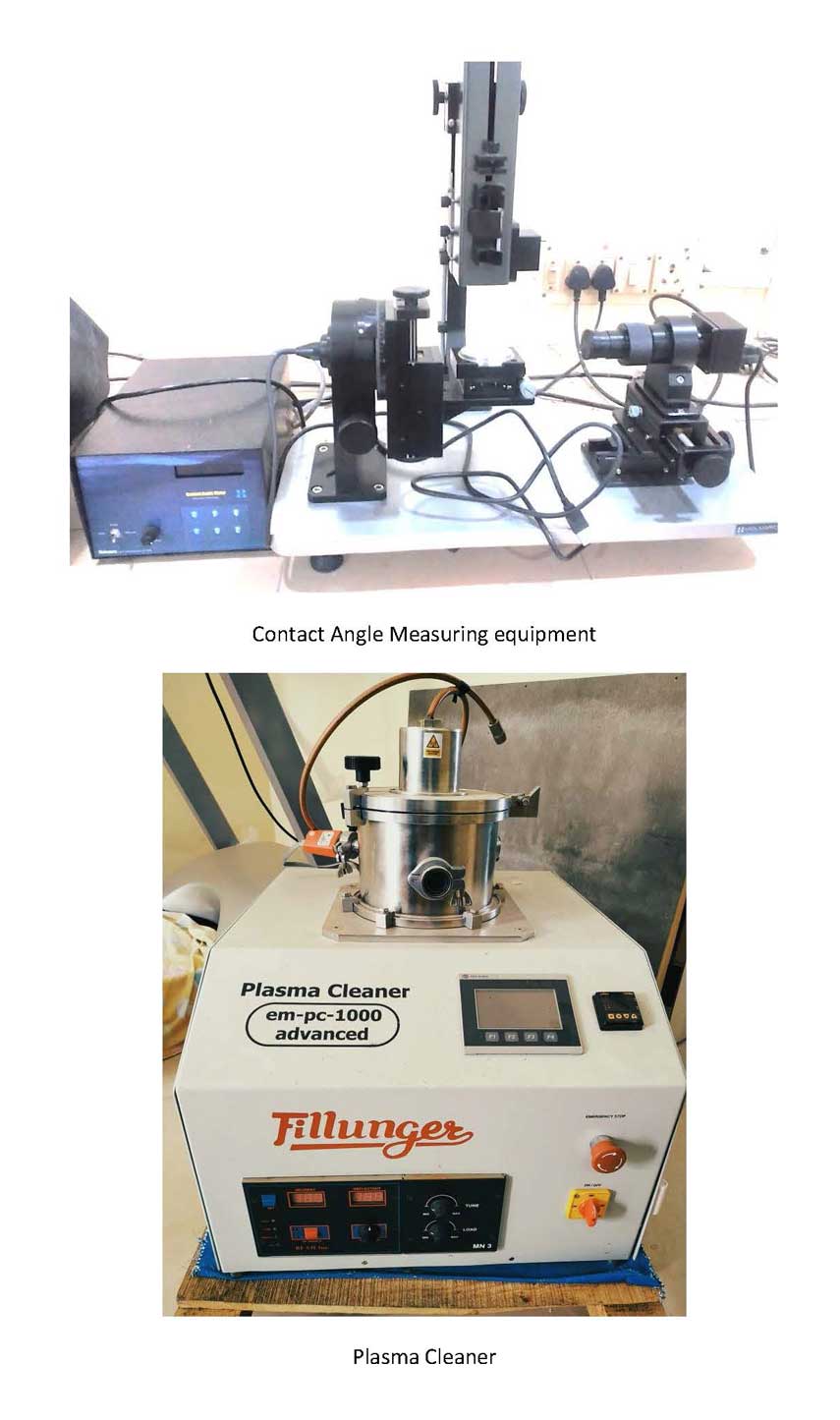

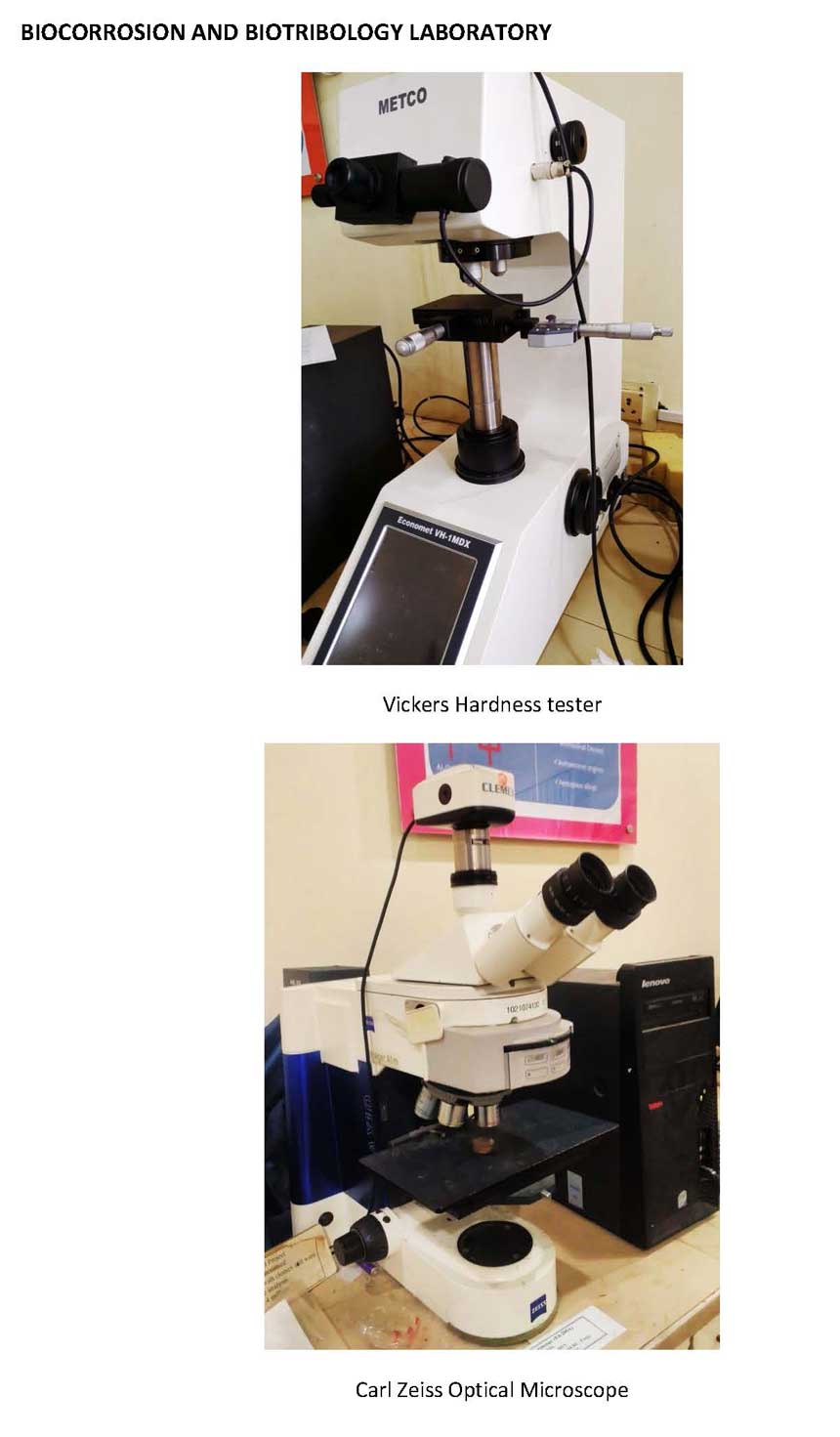

Biocorrosion and Biotribology Laboratory

Corrosion and wear are the major factors that affects the service period of an implant when exposed to the aggressive environment as in human body. Development of new materials and coatings to alleviate wear and corrosion are the major focus of biomaterials research to enhance the longevity of mankind. The major focus of this facility is to evaluate and understand the behaviour of widely used implant materials such as titanium and magnesium in simulated body conditions. The corrosion of coated and uncoated substrates are evaluated using ACM Gill potentiostat under controlled environment. A reciprocator wear tester (Ducom) with temperature, pH and environment-controlled equipment is utilized to assess wear rate and friction of materials. The scratch resistance of the thin film coatings is measured using either a static or ramp loaded scratch tester provided with 200 µm dia diamond indenter.

Lab In-charge: Dr.Mohan Varma Damu Seshadri, Email:mohanvarma@vit.ac.in

| Instrument name | Company | Number |

| Fretting wear | Ducom Instruments | 1 |

| Reciprocating wear test | Ducom TR-285-M1 | 1 |

| Scratch tester | Ducom | 1 |

| Potentiostat | ACM-GillAC | 1 |

| Contact angle measuring system | Holmarc Opto-Mechatronics Pvt. Ltd. | 1 |

| Optical Microscope | Carl Zeiss | 1 |

| Vickers hardness tester | Chennai Metco Pvt Ltd | 1 |

| Electrophoretic deposition | APLAB L1285 | 1 |

| Fume hood | Modern Lab Interior | 2 |

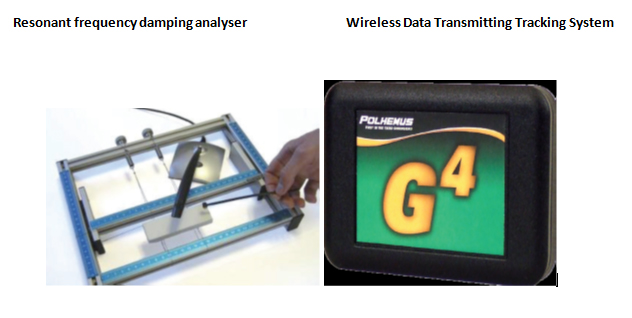

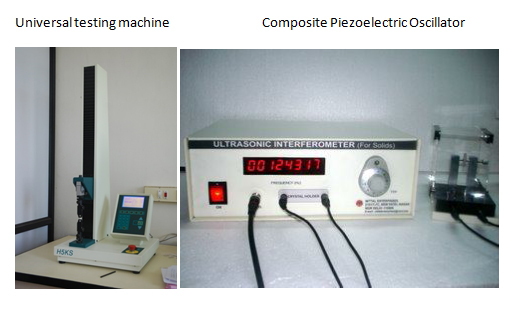

Medical Physics Laboratory

This laboratory has all the basic equipments needed to perform experiments related to medical physics applications. Medical Physics is the application of Physics concepts, theories and principles to medicine or health care.Some of the key areas of research include:

- Radiation Physics

- Growth and characterization of urinary crystals (Invitro and Invivo)

- Ultrasonics

- Biomechanics & Biomaterial characterization

- Synthesis and characterization of magnetic nanoparticle for Hyperthermia application

- Biophotonics

Lab In-charge: Dr.Arunai Nambi Raj, Email:narunainambiraj@vit.ac.in

| INSTRUMENTNAME | COMPANY | NUMBER |

|---|---|---|

| MATERIAL TESTING MACHINE | H5KS, TINIUSOLSEN, UK | 1 |

| G4 SENSOR HUB | POLHEMUS, USA | 1 |

| RADIOFREQUENCY DAMPING ANALYSER | IMCE, BELGIUM | 1 |

| PIEZOELECTRIC OSCILLATOR | MITTAL ENTERPRISES,INDIA | 1 |

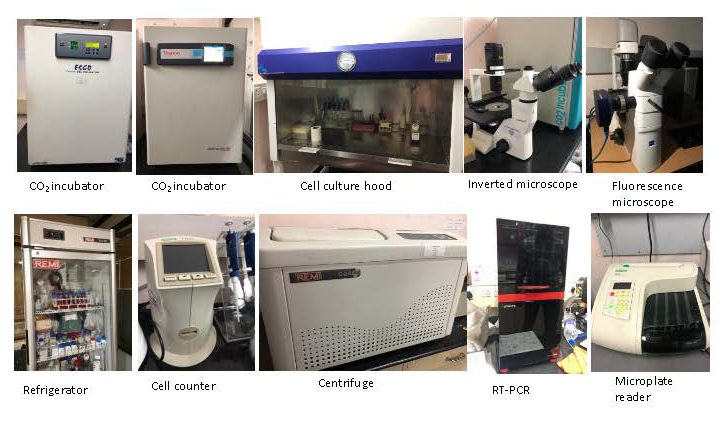

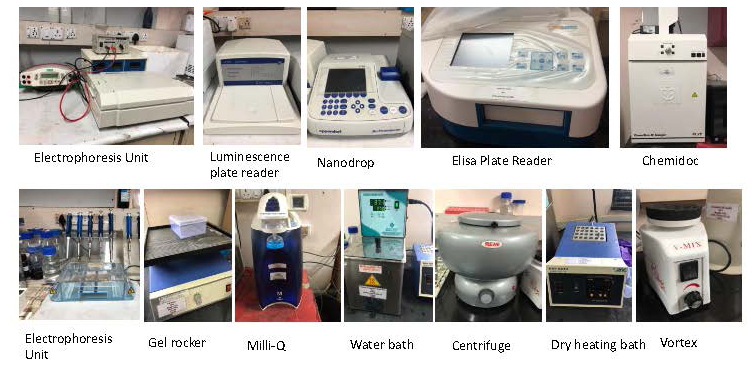

Cellular and Molecular Therapeutics Laboratory

This facility comprises of all the equipments and instruments needed to perform cellular studies and other molecular biology studies.

Lab in-charge: Dr. Loganathan Rangasamy, Email:loganathan.r@vit.ac.in

| INSTRUMENT NAME | COMPANY | NUMBER |

|---|---|---|

| BSL-2 BIOSAFETY CABINET | LARK | 1 |

| CO2 INCUBATOR | THERMOFISHER/LARK | 2 |

| AUTOMATIC CELL COUNTER | BIORAD | 1 |

| VORTEX | LARK | 1 |

| CLINICAL CENTRIFUGE | REMI | 1 |

| INVERTED PHASE CONTRAST MICROSCOPE | LABOMED | 1 |

| REFRIGIRATOR | LG/REMI | 3 |

| GEL DOCUMENTATION SYSTEM | UVP | 1 |

| COOLING CENTRIFUGE | LARK | 1 |

| DIGITAL STANDARD STEREOTACTIC INSTRUMENT | BRAINTREE SCIENTIFIC | 1 |

| LUMINOMETER | BERTHOLD | 1 |

| WESTERN BLOT APPARATUS | BIORAD | 1 |

| SEMIDRY BLOT APPARATUS | LARK | 1 |

| MICROPLATE READER | BIORAD | 1 |

| PCR THERMOCYCLER | TAKARA | 1 |

| qPCR | 1 | |

| BIOPHOTOMETER | EPPENDORF | 1 |

| -20 FREEZER | REMI/CRYOSCIENTIFIC | 2 |

| -80 FREEZER | CRYOSCIENTIFIC | 1 |

| UV VISIBLE SPECTOPHOTOMETER | LARK | 1 |

| WATER BATH | EQUITRON | 1 |

| ICE FLAKE MACHINE | LARK | 1 |

| GEL ROCKER | LARK | 1 |

| DRY BATH | LARK | 1 |

| MICROWAVE OVEN | LG | 1 |

| LIQUID NITROGEN STORAGE CONTAINER | 1 | |

| FLUORESENCE MICROSCOPE | INVITROGEN | 1 |

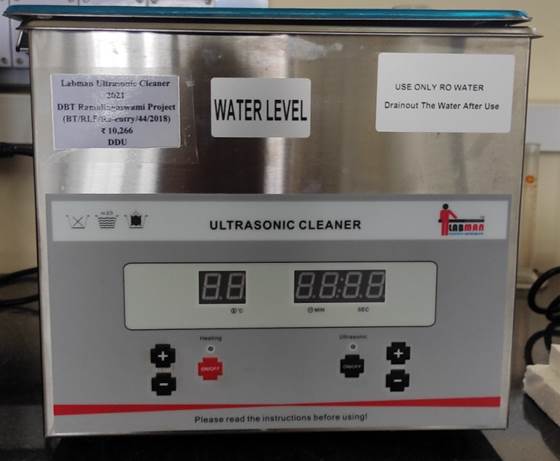

| pH METER | LABMAN | 1 |

| ROTARY BIOREACTOR | TARSON | 1 |

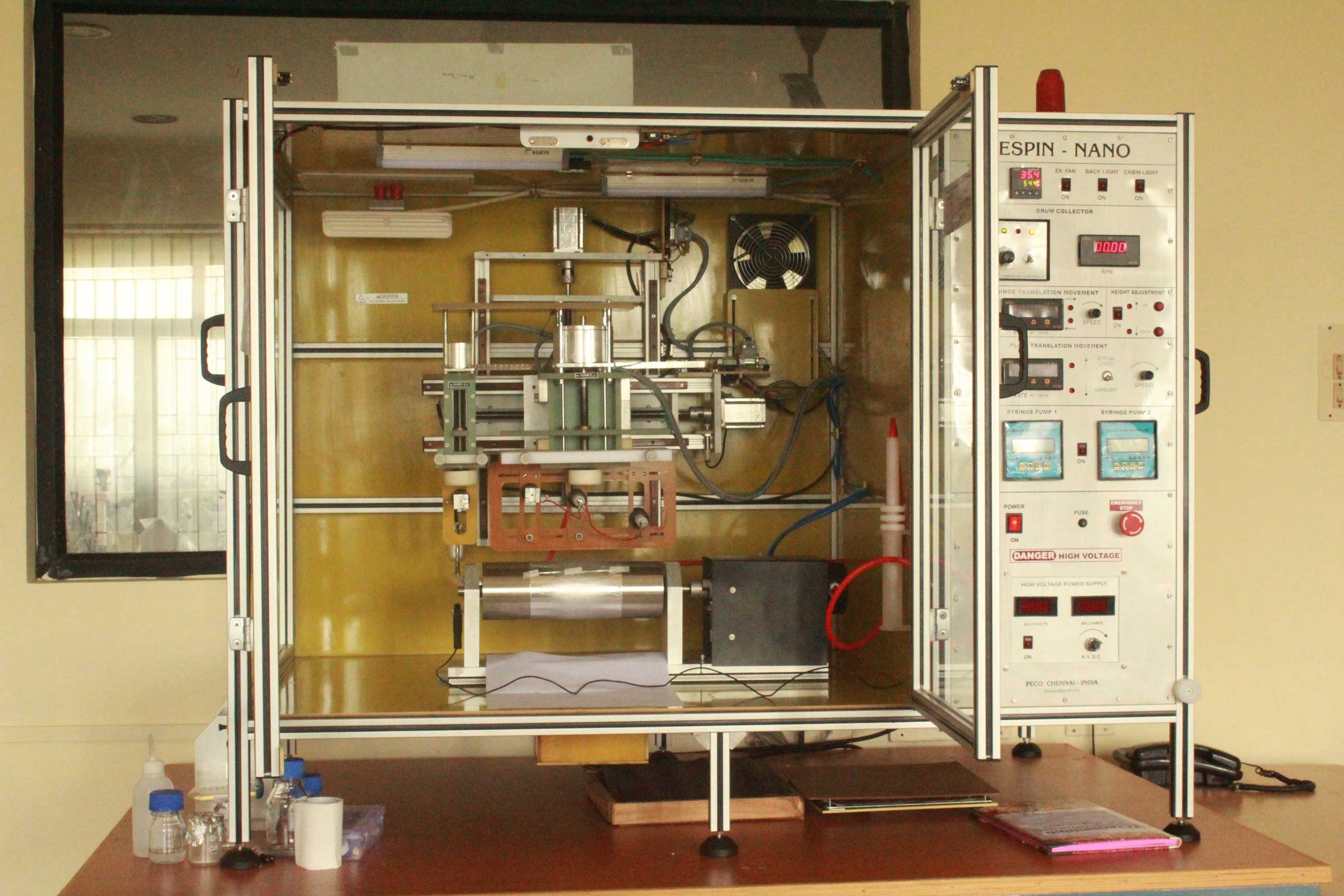

Tissue Engineering Laboratory

This facility has all the basic equipments needed to fabricate polymeric scaffolds, hydrogels and nanomaterials which are crucial for tissue engineering lab.

Lab in-charge: Dr.Amit Kumar Jaiswal, Email: mailto:amitj@vit.ac.in

| INSTRUMENT NAME | COMPANY | NUMBER |

|---|---|---|

| SHAKER INCUBATOR | REMI | 1 |

| REFERIGIRATOR | SAMSUNG/LG/REMI | 3 |

| BSL2 BIOSAFETY CABINET | ESCO BIOTECH | 1 |

| CO2 INCUBATOR | ESCO BIOTECH | 1 |

| INVERTED MICROSCOPE | MAGNUS | 1 |

| COOLING CENTRIFUGE | REMI | 2 |

| ANALYTICAL BALANCE | SARTORIOUS | 1 |

| DIGITAL 5 POSITION MAGNETIC STIRRER | REMI | 1 |

| MAGNETIC STIRRER | TARSON | 1 |

| PH METER | SYSTRONICS | 1 |

| FREEZE DRIER | MARTIN CHRIST | 1 |

| HOT PLATE WITH MAGNETIC STIRRER | REMI | 1 |

| SPINIX ORBITAL SHAKER | TARSON | 1 |

| VORTEX MIXER | REMI | 1 |

| MICROBALANCE | SHIMADZU-UNIBOC | 1 |

| SPINWIN MICRO CENTRIFUGE | TARSON | 1 |

| CLINICAL CENTIFUGE | REMI | 1 |

| HOT AIR OVEN | TECHNICO LAB PRODUCT | 1 |

| ELISA PLATE READER | LEADS INDIA LABORATORY EQUIPMENTS INC. | 1 |

| -20 FREEZER | CRYOSCIENTIFIC | 1 |

| DOUBLE DISTILLATION UNIT | AIR BLOW | 1 |

| BACTERIOLOGICAL INCUBATOR | LARK | 1 |

| AUTOCLAVE | BIOTECH ENGINEERING | 1 |

| ELECTROSPINNING SETUP | ESPIN | 1 |

| MILLIPORE® DIRECT®-Q 3 WITH UV WATER PURIFIER | MERCK | 1 |

Antimicrobial Studies Laboratory

This laboratory has all the basic equipments needed to perform anti-microbial studies.

Lab in-charge: Dr.Raunak Kumar Das, Email: raunakkumardas@vit.ac.in

| INSTRUMENTNAME | COMPANY | NUMBER |

|---|---|---|

| LAMINAR AIR FLOW HOOD | CLEAN AIR | 1 |

| SHAKER INCUBATOR | REMI | 1 |

| REFRIGERATOR | WHIRLPOOL | 1 |

Biomaterials Processing Laboratory

Key challenges in the field of implantology are stress shielding, low fatigue strength, poor bone bonding and formation of biofilim on implants. This laboratory has all the basic equipments needed for the development of materials with tailored mechanical properties. Materials with grain size ranging from micron and to nano are being investigated to have optimum modulus closer to bone and high fatigue and mechanical strength. Two high temperature furnaces with controlled environment is available to facilitate this work. In addition, novel coatings to improve the osseointegration and prevent bacterial formation are developed using simple cost-effective techniques such as Electrophoretic deposition (EPD) and micro arc oxidation (MAO). In addition, this laboratory also involves activities related to replacement and reconstruction of diseased or damaged parts of the musculo-skeletal/dental systems by near net shape manufacturing of implants using different material and biological characterizations. Further, this lab focuses on development of new generation of ceramic, ceramic- polymeric/metallic composites for different biomedical applications. A substantial portion of this lab is involved in colloidal process of ceramics, bio-ceramics, protein coagulation casting, sol-gel and implant designing (dental and maxillofacial prosthesis) for bio-medical applications.

Lab In-charge: Dr.Suya Prem Anand, Email:suyapremanand.p@vit.ac.in

| Instrument Name | Company | Number |

|---|---|---|

| Plasma Cleaner | Fillunger | 1 |

| Tubular Furnace | VB Ceramics | 1 |

| Box Furnace | VB Ceramics | 1 |

| Slow speed diamond saw | Chennai Metco | 2 |

| Hot air oven | THE.I.L.E.CO | 1 |

| Disc polishing machine | Chennai Metco | 1 |

| Mounting Machine | Chennai Metco | 1 |