CO2 Research and Green Technologies Centre

Research Activities in CO2 Research and Green Technologies Centre

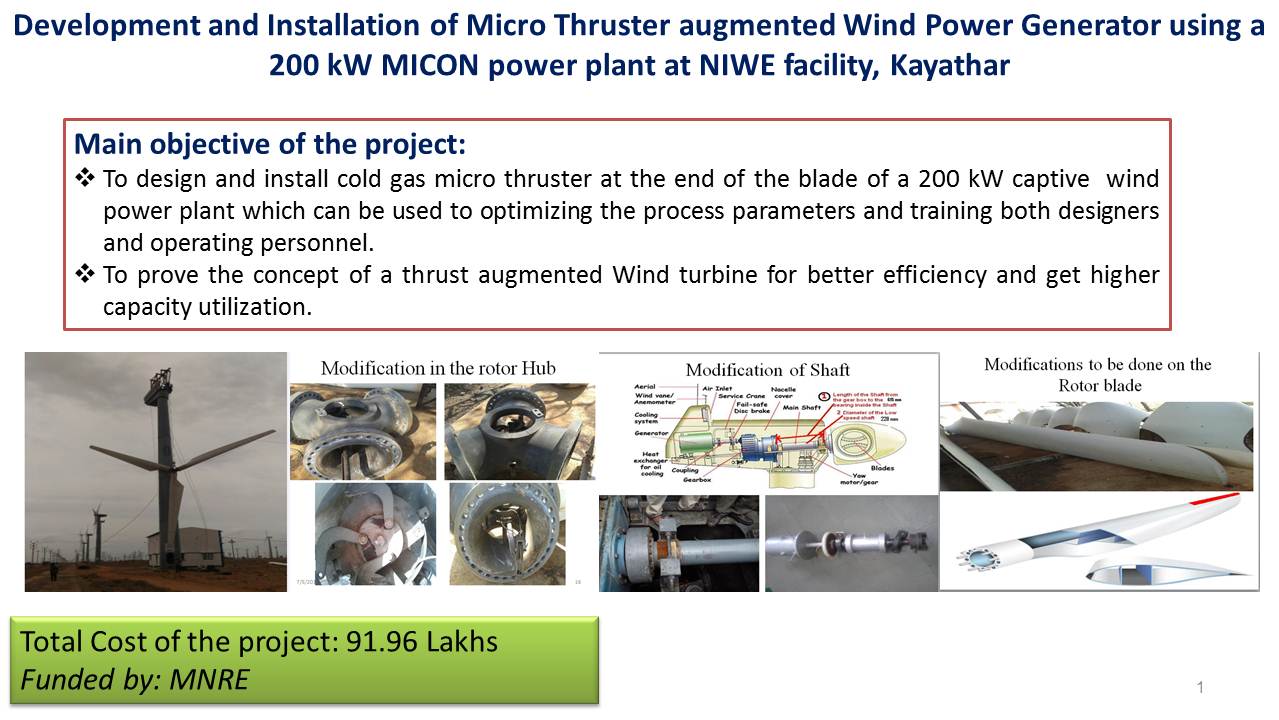

Development and Installation of Micro Thruster augmented Wind Power Generator using a 200 kW MICON power plant at NIWE facility, Kayathar

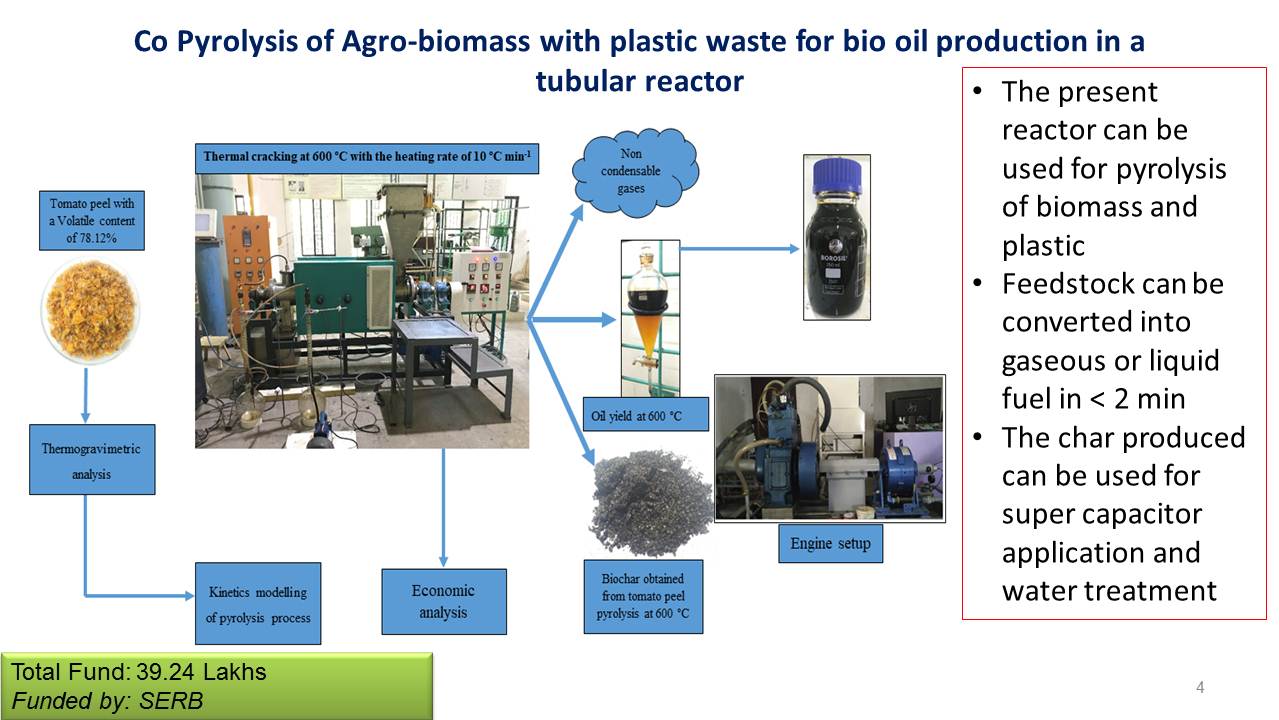

Co Pyrolysis of Agro-biomass with plastic waste for bio oil production in a tubular reactor

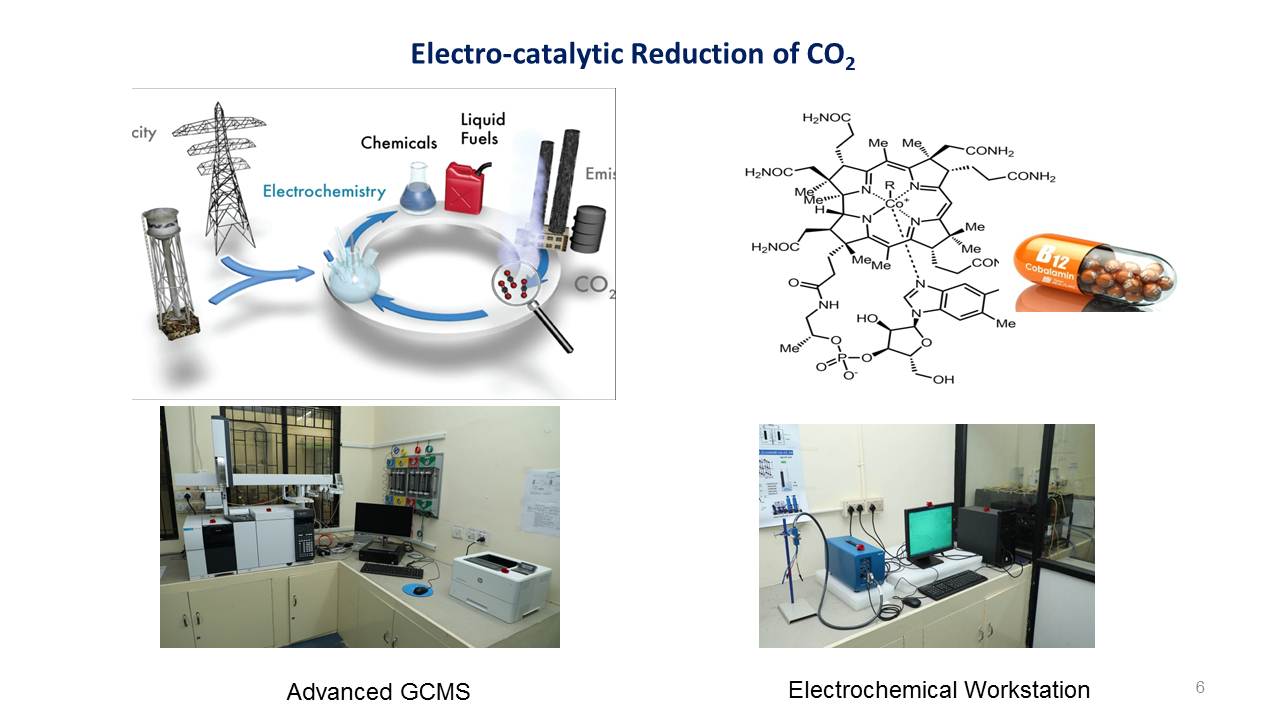

Electro-catalytic Reduction of CO2

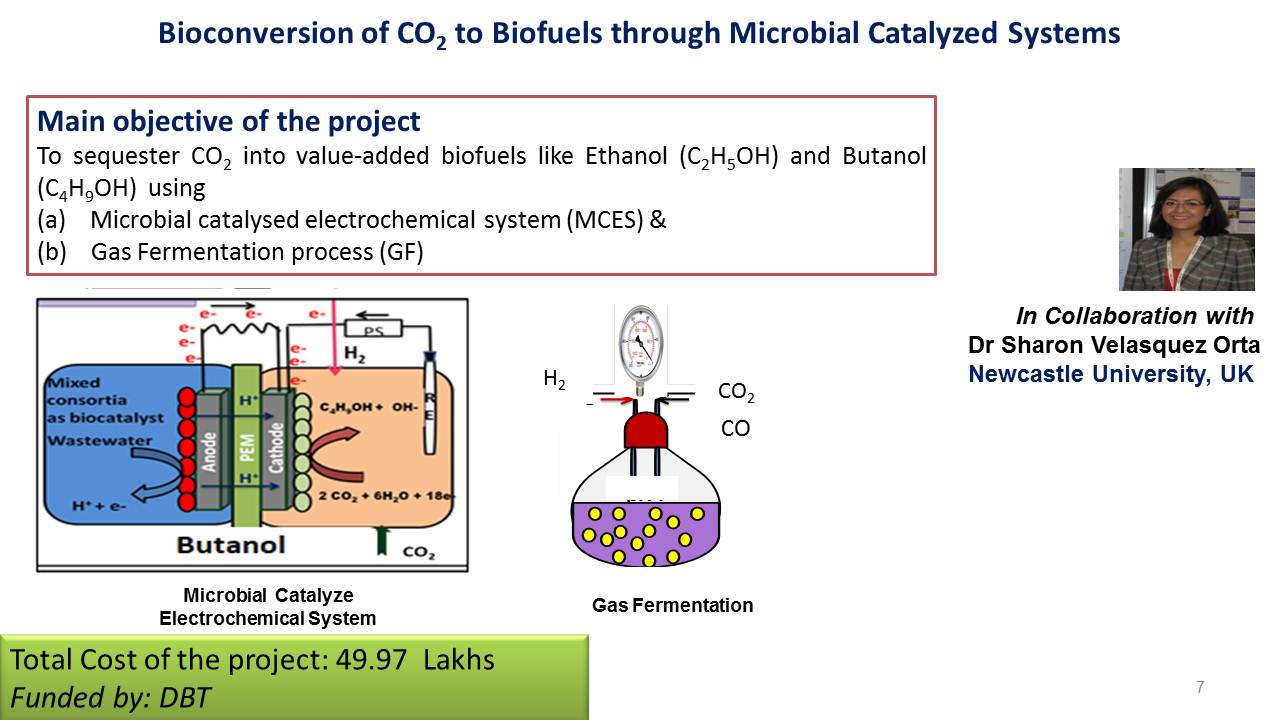

Bioconversion of CO2 to Biofuels through Microbial Catalyzed Systems

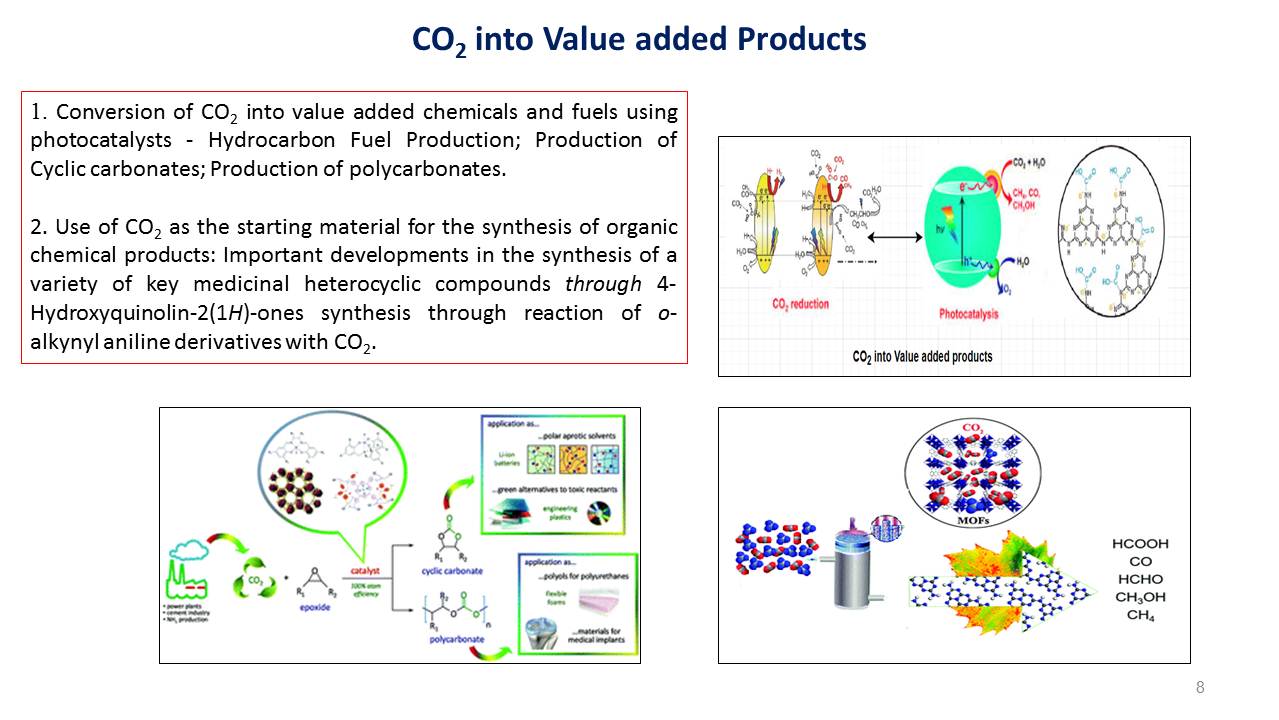

CO2 into Value added Products

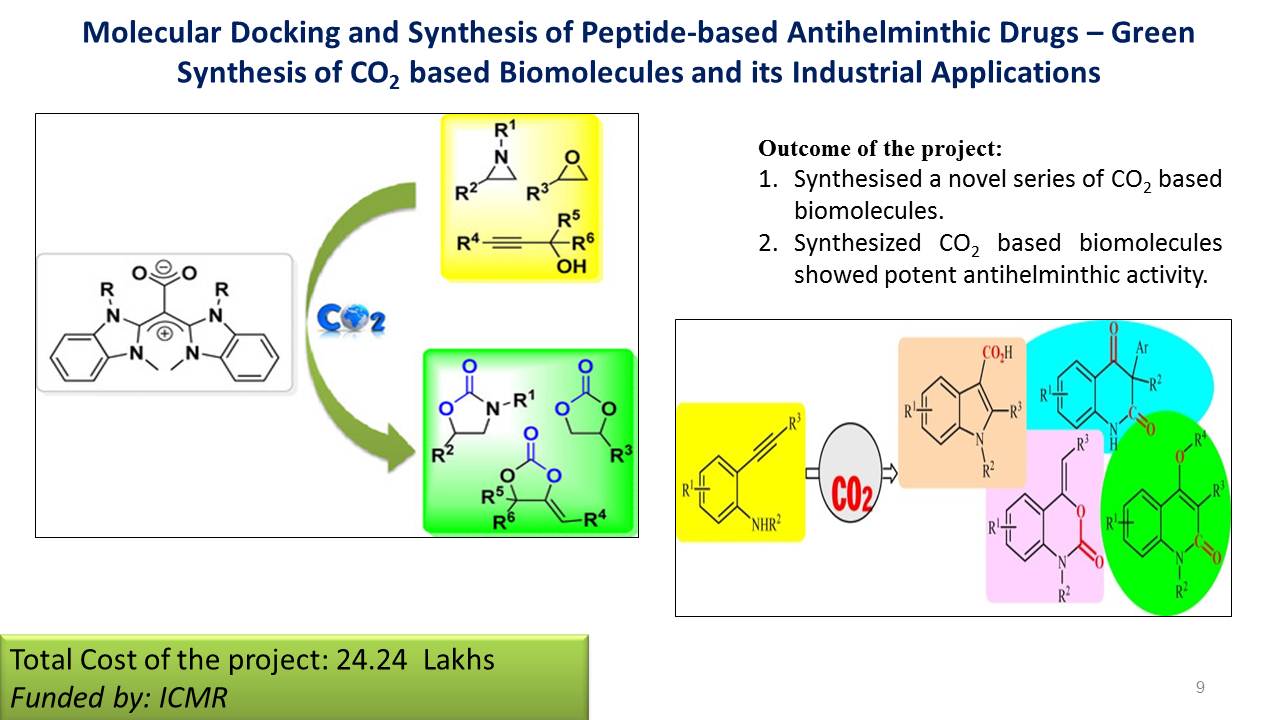

Molecular Docking and Synthesis of Peptide-based Antihelminthic Drugs – Green Synthesis of CO2 based Biomolecules and its Industrial Applications

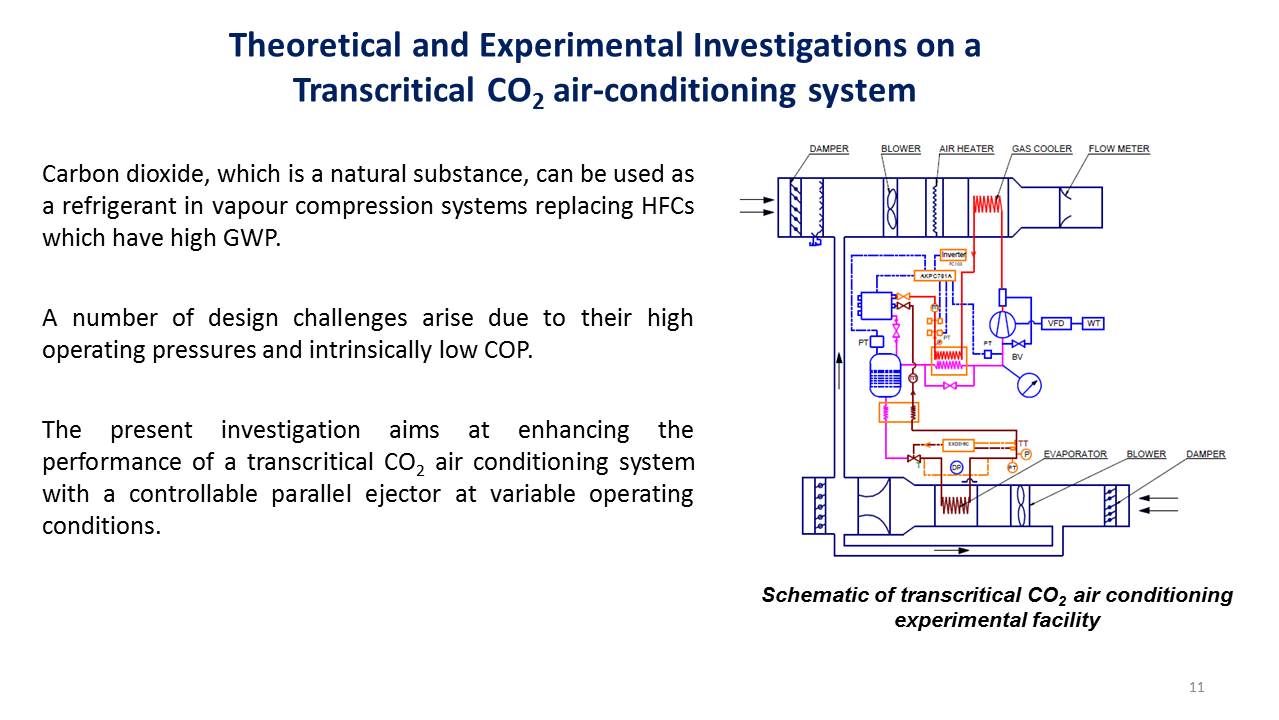

Theoretical and Experimental Investigations on a Transcritical CO2 air-conditioning system

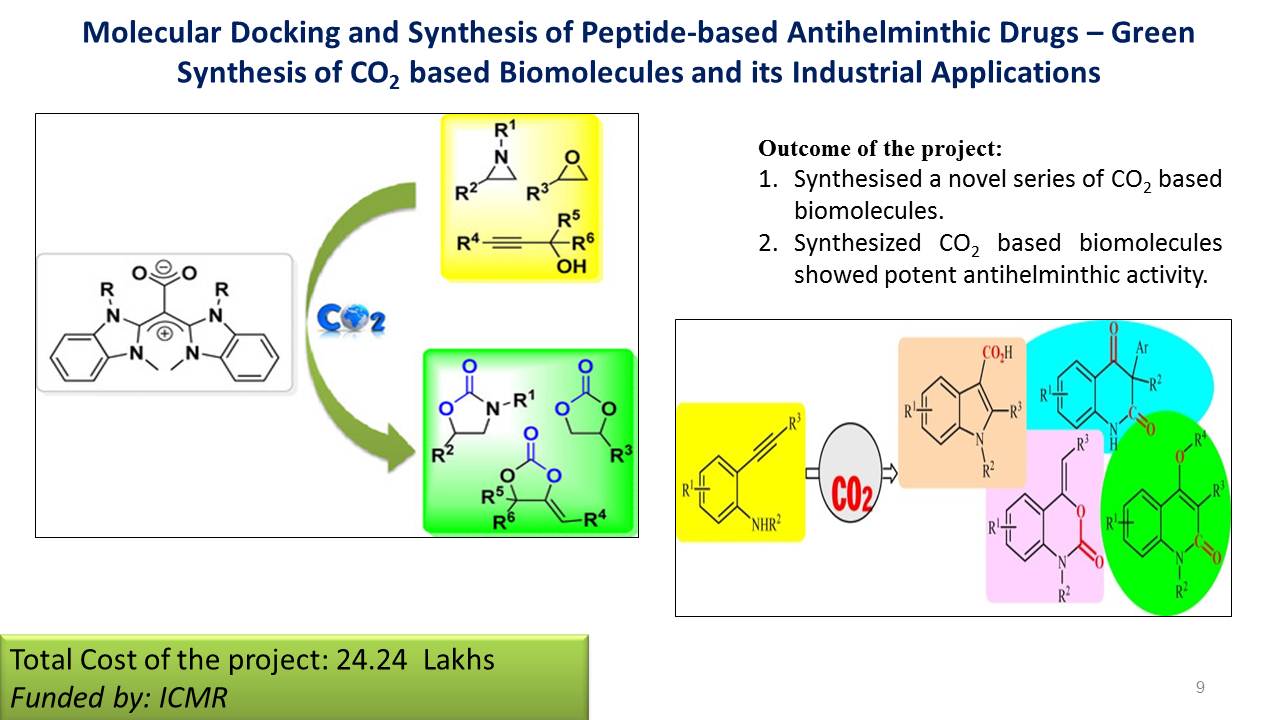

Molecular Docking and Synthesis of Peptide-based Antihelminthic Drugs – Green Synthesis of CO2 based Biomolecules and its Industrial Applications

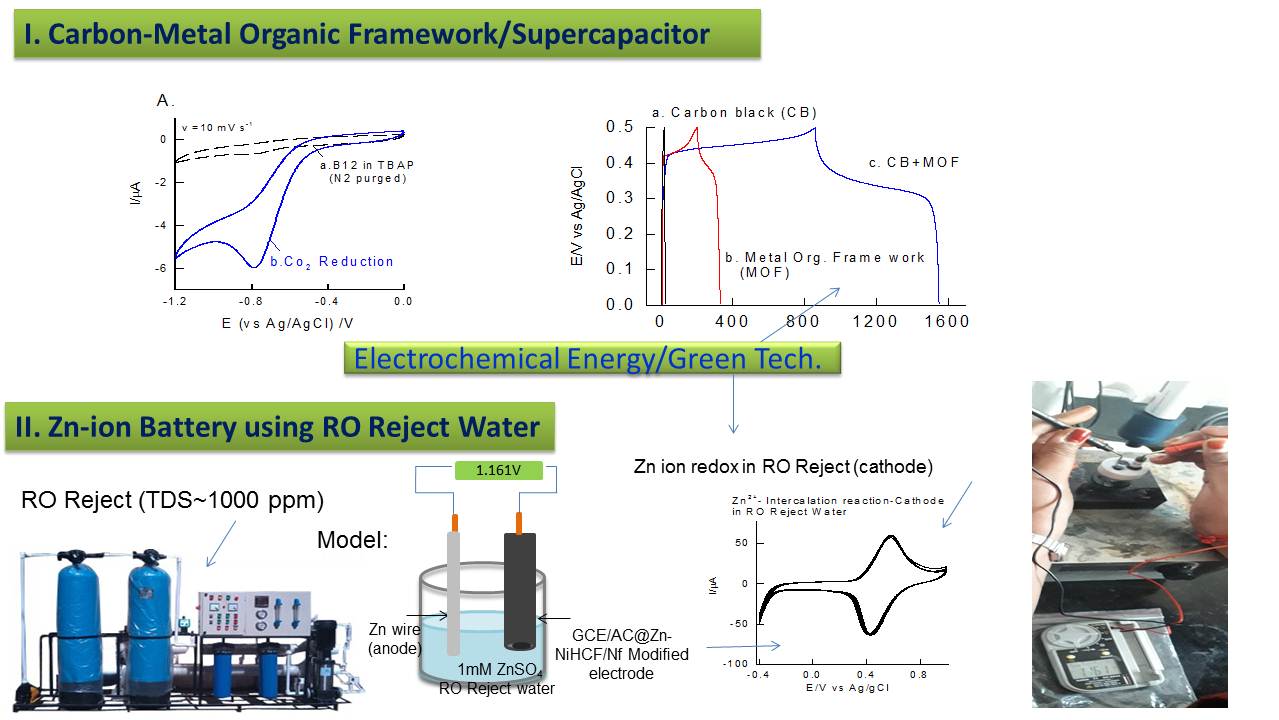

Carbon-Metal Organic Framework/Supercapacitor

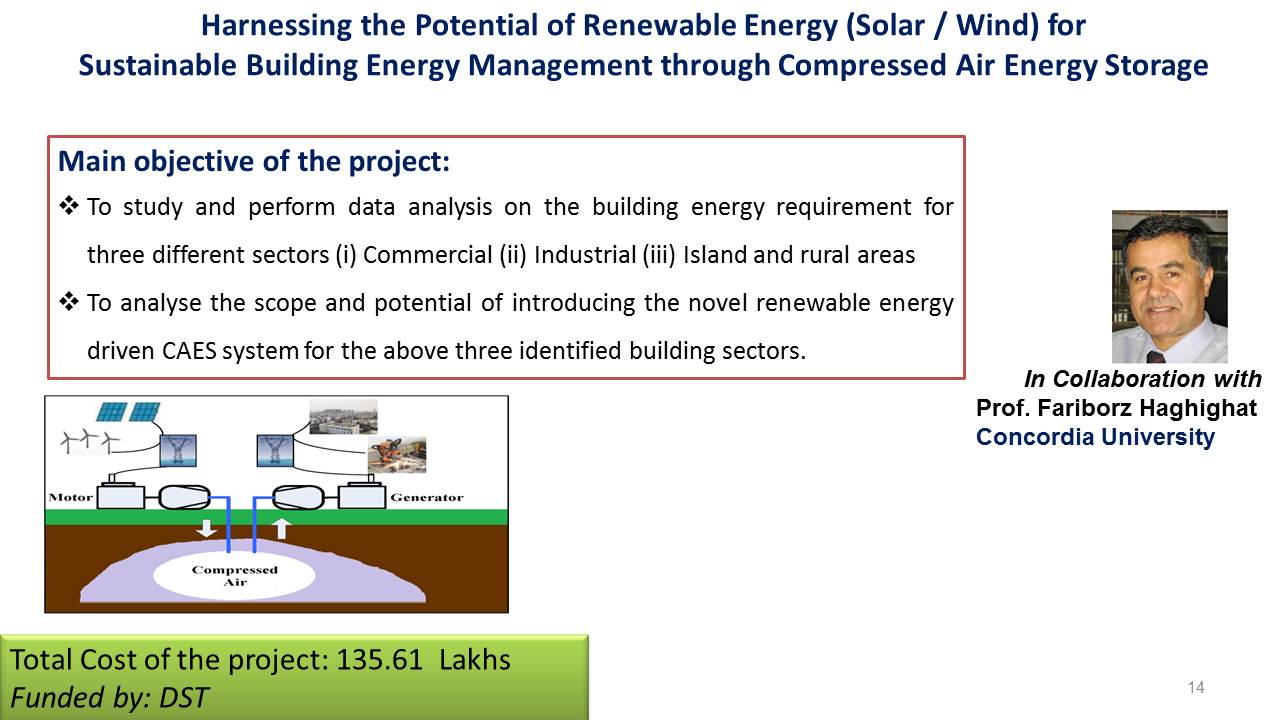

Harnessing the Potential of Renewable Energy (Solar / Wind) for Sustainable Building Energy Management through Compressed Air Energy Storage

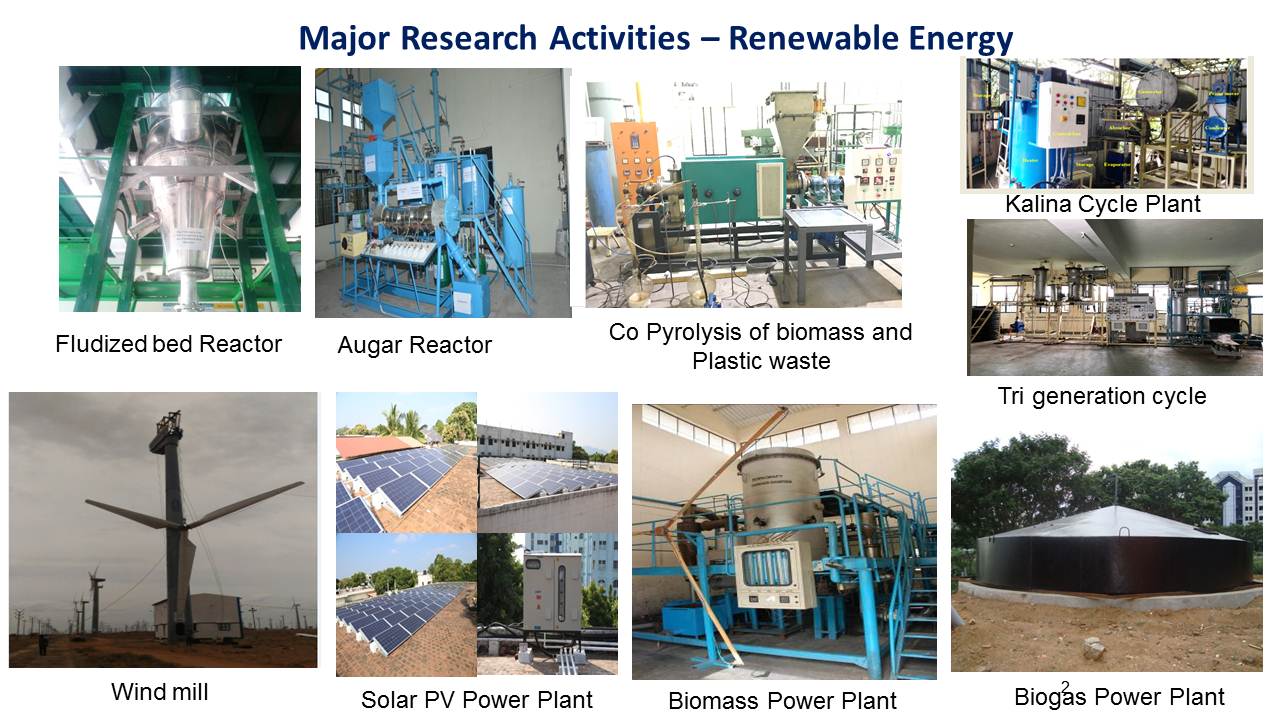

Major Research Activities – Renewable Energy

last updated:June 12, 2020