Centre for Functional Materials (CFM)

Service Platform

The Director

Centre for Functional Materials

Vellore Institute of Technology

Vellore-632014. Tamil Nadu, India.

Email: cfm@vit.ac.in

Contact:0416-220-2350

Prof. Amlan Das

(Professor Incharge)

Contact: 8456805997

Payment Details

| Studies | Make and Model | Charges (/sample) | In-charge |

| Vicker’s andKnoop hardness | Mitutuoyo-HB210 | Rs. 500 /- | Dr. R Ezhil Vizhi |

| Z-Scan | Coherent 640 OBIS | Rs. 500 /- | Dr. R Ezhil Vizhi |

| Laser DamageThreshold | Litron Lasers He-Ne Laser-632nm | Rs. 500 /- | Dr. Amlan Das |

| Laser ShockPeening | Litron Lasers | Rs. 1000 /- | Dr. Amlan Das |

Vicker’s and Knoop hardness Studies

It will be operated by putting a controlled force on the surface of the material over a period of time. After a particular indenter is pressed into the surface under testing, the indentation resulting from it is measured and the software is also used to analyze and generate precise results.

Specifications:

Make and Model: Mitutuoyo-HB210

Indent : Diamond Indenter

Magnification : 10x and 50x

Load : 10 to 1000 kgf (load applied for 10 to 15 seconds)

Vicker’s hardness and Knoop Hardness with AVPAK software

Contact person: Dr. R Ezhil Vizhi, CFM, VIT Vellore

Sample Preparation

For a high-accuracy measurement, the test should be performed on a flat specimen with a polished or prepared surface. The quality of the required surface is dependent on the force used. In all tests, the indentation perimeter and depth should be clearly defined when observed by the microscope.

Charges per sitting (1- 2 hrs): Rs. 500 /- per sample

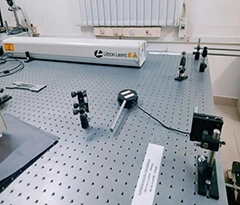

Z-Scan Technique

Z-scan technique is used to measure the nonlinear optical properties of materials. The Z-Scan helps to determine intrinsic photo-physical properties of materials by focusing a single laser beams onto the surface of the materials sample. Usually, measurements need to be taken at different laser pulse energies or different laser pulse lifetimes in order to determine what nonlinear processes are present.

Specifications:

Laser Made : Coherent 640 OBIS

Laser wavelength : 640 nm

Software : Coherent connections

Z- Scan controller unit made: Holmarc

Maximum output power: 44 mW

Contact person: Dr. R Ezhil Vizhi, CFM, VIT Vellore

Sample Preparation

Sample (of size 1mm x 1- 10 mm x 1-10 mm) should be flat with a polished surface.

Charges per sitting (1 hrs): Rs. 500 /- per sample

Laser Damage Threshold

The laser damage threshold (LDT) or laser induced damage threshold (LIDT) is the limit at which an optic or material will be damaged by a laser given the fluence (energy per area), intensity (power per area), and wavelength. LDT values are relevant to both transmissive and reflective optical elements and in applications where the laser induced modification or destruction of a material is the intended outcome.

Litron Lasers

He-Ne Laser-632nm

Contact person: Dr. Amlan Das, CFM, VIT Vellore

Sample Preparation

Sample (of size 1mm X 1- 10 mm X 1-10 mm) should be flat with a polished surface.

Charges per sitting (1 hrs): Rs. 500 /- per sample

Laser Shock Peening Setup

“A process of materials that induces residual compressive stresses on the surface of a component due to shock waves produced by plasma’. Laser peening (LP), or laser shock peening (LSP), is a surface engineering process used to impart beneficial residual stresses in materials. Laser peening uses the dynamic mechanical effects of a shock wave imparted by a laser to modify the surface of a target material. Fundamentally, laser peening can be accomplished with only two components: a transparent overlay and a high energy pulsed laser system. The deep, high-magnitude compressive residual stresses induced by laser peening increase the resistance of materials to surface-related failures, such as fatigue, fretting fatigue and stress corrosion cracking.

Litron Lasers

Nd-YAG Laser

Energy – 400 mJ

Laser Wavelength – 1064nm

Pulsed duration – 6ns

Contact person:Dr. Amlan Das, CFM, VIT Vellore

Sample Preparation

Metal/metal alloy (1mm thick X 5-20 mm width X 5-20 mm length) with flat surface.

Charges per sitting (1 hr): Rs. 1000 /- per sample

All the rates are inclusive of Service Tax as per Government of India Rules.

- Payment is only through online mode. No DD/Cheque is accepted.

- Please send the printed online fee receipt along with the payment details form.

- Reports will be released only when full payment is received.

- Radioactive/Explosive/Unstable samples are NOT accepted for analysis.

- It is mandatory for user of “CFM Facility – VIT, Vellore” to duly acknowledge the facility in all publications of research work, where in the services of the CFM at VIT have been made use of and communicate the same to CFM VIT, Vellore.

*Mode of payment only through online by using the following link and attach the printed receipt along with the Payment Details Form given below

- "Please use the browsers Mozilla Firefox / other browser (except chrome) / mobile device for paying the fee"